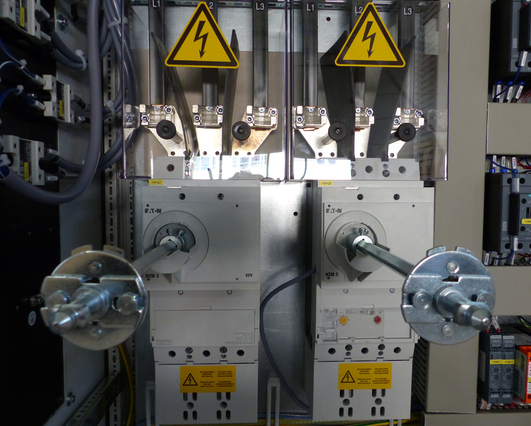

Control systems

Volta GmbH & Co KG offers control systems suitable for different projects and products. The spectrum ranges from complete control cabinets for heating registers in the megawatt range in the industrial and power plant industries to solutions developed for HVAC customers and their products.

Thanks to Volta's know-how and experience, the components, their composition and functional planning are ideally aligned to the respective requirements of the regulation.

We are also happy to answer your questions, requests and suggestions by phone.

Gallery

Control systems

What actual values are there whose changes are to be controlled?

ACTUAL value 1:

The final air temperature should be adjusted.

(The final air temperature should be kept constant at a setpoint at various inlet temperatures)

ACTUAL value 2:

The air flow is constant at 100%

The air flow changes within known limits and the final air temperature should be adjusted.

(e.g. the air flow fluctuates between 40% and 100%, the final air temperature should be at various inlet temperatures are kept constant at a setpoint)

No. |

Description of control system |

Actual-Value 1 |

Actual-Value 2 |

Control function |

1.00 |

Use of multiple switching groups(on-site realisation) |

|

|

easy |

2.00 |

Control by temperature monitors and contactors in the control cabinet(onsite realisation) |

|

|

Thermostatic |

3.00 |

Electronic control with solid state relay and 1 process controller |

|

|

constant control |

4.00 |

Constant room temperature control for small outputs |

|

|

constant control |

4.01 |

Constant room temperature control for small outputs,with duct sensor, flow monitor |

|

|

constant control |

6.00 |

Electronic double control with solid state relay,2 process controllers |

|

|

constant control |

6.01 |

Electronic double control with solid state relay,1 process controller and 1 temperature monitor |

|

|

constant control |

6.02 |

Electronic double control with solid state relay,1 process controller and 1 flow monitor |

|

|

constant control |

7.00 |

Electronic double regulation with Thyrotakt control,2 process controllers |

|

|

constant control |

7.01 |

Electronic double regulation with Thyrotakt control,1 process controller and 1 temperature monitor |

|

|

constant control |

7.02 |

Electronic double regulation with Thyrotakt control,1 process controller and 1 flow monitor |

|

|

constant control |

Additional options for control systems

Special designs according to customer requirements and additional controls can be provided on request can be implemented, such as:

- Motor controls, three-phase and alternating current, possibly with different speeds and start-up circuits

- Messages of all kinds such as group messages, fault messages, limit value messages, operating messages and the like.

- Communication with existing controls, e.g. Control rooms or upstream plant parts etc.

- Special voltages